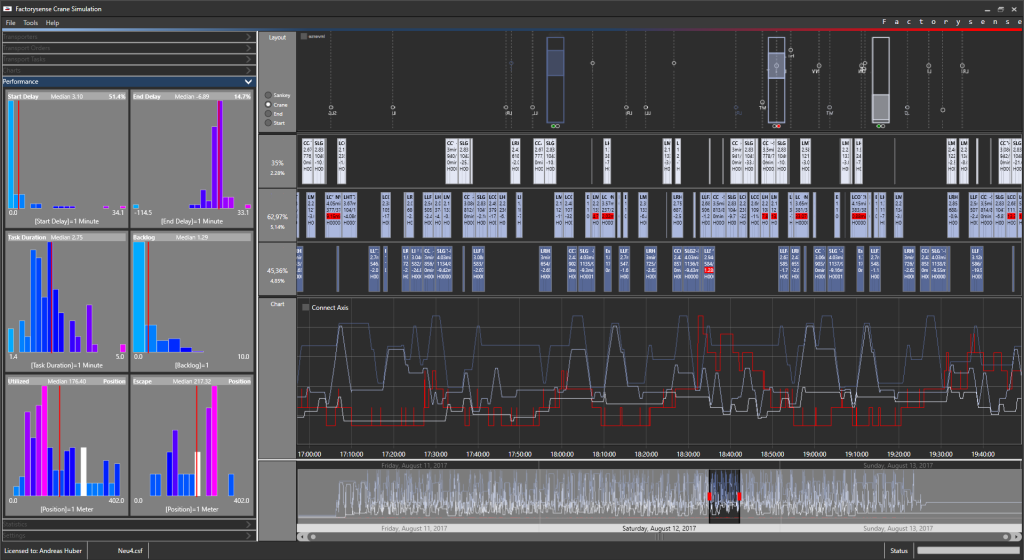

Factorysense Crane Simulation

Overview

Application- Usable in any industry

- Investigation of charging areas, teeming bays, or stock yards

- Scenarios simulation to determine the number of required cranes

- Calculation of crane trajectories in 3 dimensions (x-, y- and z-axis)

- Feasibility check for production schedules

- Definition of material flow as a consequence of crane capacity

- Automatic Crane Scheduling

- Assignment of transport orders to crane bridges

- Calculate movements for collission avoidance

- Optimization based on mixed integer and linear programming solvers

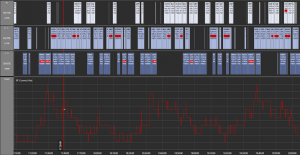

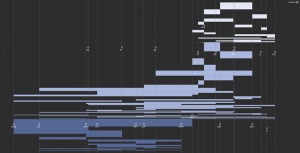

- Gantt chart to visualize transports of specific crane bridges over time

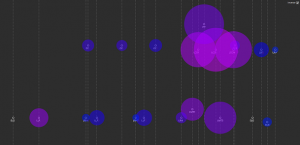

- Interactive rendering of crane, bridge, and trolley position in a scaled layout

- Sankey-diagram for evaluation of material flow

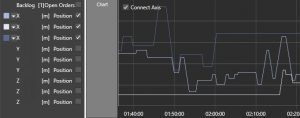

- Charts to provide information about the crane position and order backlog over time

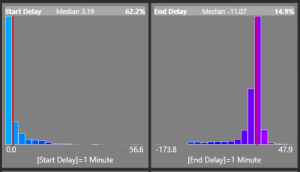

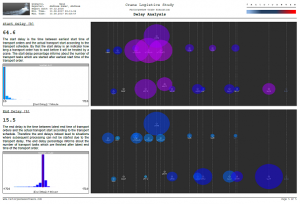

- Interactive histograms to visualize statistical distributions of key performance indicators

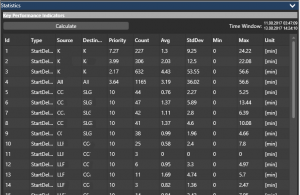

- Analysis grid for key performance indicators

- Import of Transport orders from csv files i.e. created with spreadsheet applications (Microsoft Excel, …)

- File interface to import data directly from Factorysense Steel Control

- Export of Factorysense 4D transport segments, for purposes of 3D visualization

Features

Crane Position Diagrams