Factorysense Steel Control

Overview

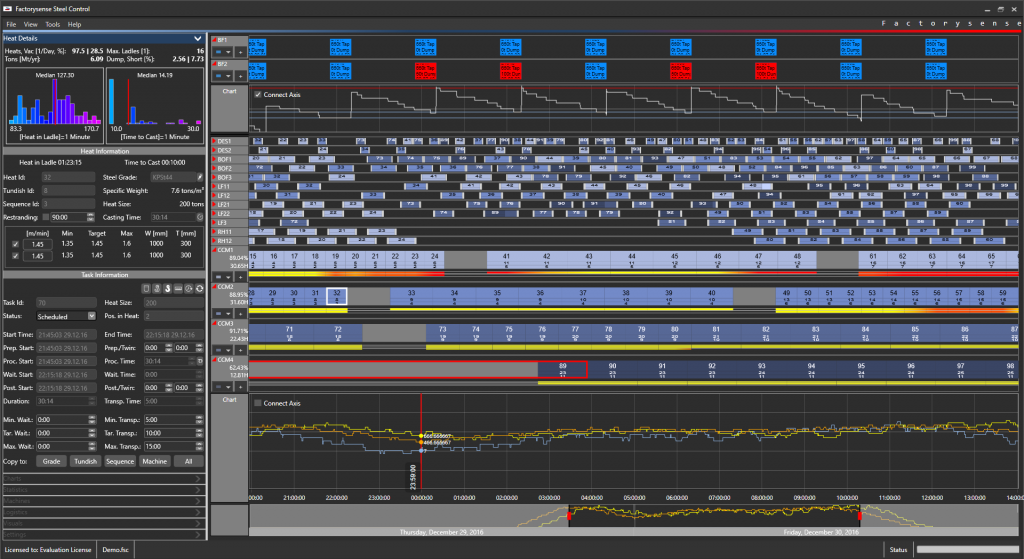

Application- Plan production rates of steel making plants

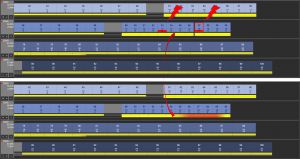

- Align iron production steel making production with continuous casting

- Define production routes and assign heats to machines

- Featuring electric arc furnace and converter steel making plants

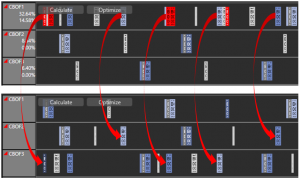

- Optimization for heat pacing calculation

- Calculate casting speeds within feasible ranges

- Optimization algorithms based on mixed integer and linear programming solvers

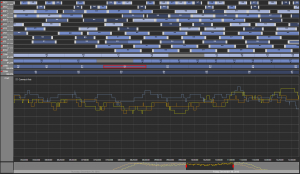

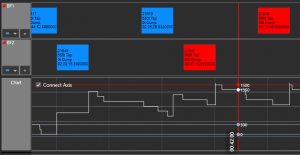

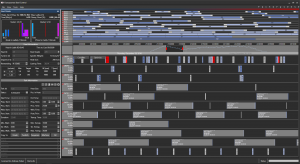

- Interactive Gantt chart for best assignment to available machines

- Steel production, steel consumption, and casting speed charts

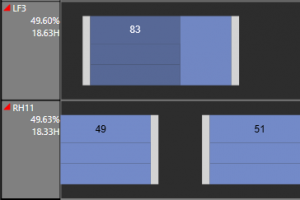

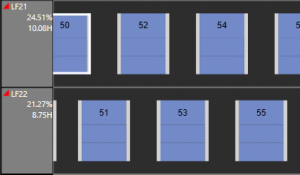

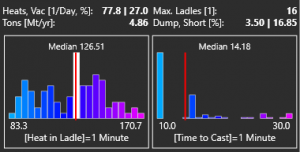

- Interactive histograms to visualize statistical distributions of key performance indicators

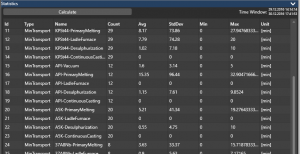

- Analysis grid for key performance indicators

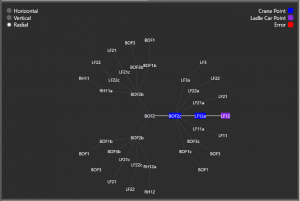

- Export of Transport orders to csv file for later import into Factorysense Crane Simulation

- Export of Factorysense 4D transport segments, for purposes of 3D visualization

Features

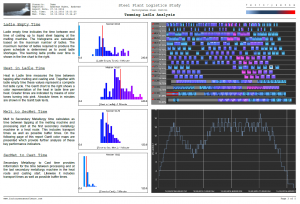

Number of Teeming Ladles